Utilizing such a structured approach fosters a safety-conscious work environment, leading to fewer incidents and injuries. This proactive risk management approach not only protects workers but also minimizes potential project delays and associated costs. Furthermore, documented procedures provide a consistent framework for training and auditing, enhancing overall operational efficiency and demonstrating a commitment to regulatory compliance.

This structured methodology is applicable across diverse industries and operational contexts, from construction and manufacturing to laboratory settings and maintenance activities. Key aspects to consider when developing these procedures include hazard identification, risk assessment, control selection, and communication strategies. Let’s explore these elements in detail.

1. Hazard Identification

Hazard identification forms the cornerstone of a robust safe method work statement template. Without a thorough understanding of potential dangers, subsequent steps like risk assessment and control selection become ineffective. This process involves systematically examining all aspects of a task to pinpoint potential sources of harm. This encompasses not only obvious physical hazards like moving machinery or working at heights but also less apparent dangers such as chemical exposure, ergonomic risks, and psychosocial factors like stress and fatigue. For instance, in a welding operation, hazards might include sparks, fumes, and ultraviolet radiation, while an office environment might present ergonomic risks from prolonged computer use.

The effectiveness of hazard identification directly influences the quality and comprehensiveness of the resulting documentation. A robust process typically involves a combination of techniques, including task analysis, walkthrough surveys, historical incident data review, and consultation with experienced personnel. By considering various perspectives and data sources, a more complete picture of potential hazards emerges. For example, analyzing past incidents can reveal patterns or recurring issues that might not be immediately apparent during a task analysis. Similarly, consulting experienced workers can provide valuable insights into less obvious hazards or near misses.

Accurate and comprehensive hazard identification is crucial for preventing workplace incidents and ensuring worker safety. Failure to identify potential hazards can lead to inadequate control measures, increasing the likelihood of accidents and injuries. Moreover, a thorough hazard identification process contributes to a proactive safety culture, demonstrating a commitment to worker well-being and regulatory compliance. Challenges in hazard identification can include overlooking less obvious hazards, inadequate consultation, and a lack of ongoing review. Addressing these challenges requires a systematic approach, utilizing diverse methodologies, and fostering a culture of continuous improvement.

2. Risk Assessment

Risk assessment is an integral component of a safe method work statement template. Following hazard identification, risk assessment analyzes the potential severity of identified hazards and the likelihood of their occurrence. This process provides a structured approach to prioritizing hazards and developing appropriate control measures. Without a thorough risk assessment, mitigation efforts may be misdirected, leaving critical vulnerabilities unaddressed.

- Severity DeterminationSeverity considers the potential consequences of a hazard, ranging from minor injuries to fatalities. For example, a trip hazard might be classified as low severity, while working at heights without fall protection would be considered high severity. Accurately determining severity is crucial for allocating resources and prioritizing control measures.

- Likelihood EstimationLikelihood refers to the probability of a hazard leading to an incident. This can be influenced by factors such as the frequency of exposure, the working environment, and the competence of personnel. A task performed infrequently in a controlled environment might have a low likelihood of incident, whereas a frequently performed task in a hazardous environment would have a higher likelihood.

- Risk Matrix UtilizationRisk matrices are commonly used to visualize and prioritize risks based on their likelihood and severity. The matrix assigns a risk rating based on the intersection of these two factors, allowing for easy comparison and prioritization. This visual representation aids in decision-making regarding control measures and resource allocation.

- Control Hierarchy ImplementationRisk assessment informs the selection of appropriate control measures based on the hierarchy of controls. This hierarchy prioritizes the most effective controls, starting with elimination and substitution, followed by engineering controls, administrative controls, and finally, personal protective equipment. For example, eliminating the need to work at heights is preferable to relying solely on fall protection equipment.

By systematically evaluating and prioritizing risks, a robust risk assessment process ensures that the safe method work statement template provides effective protection for workers. This process forms the foundation for selecting appropriate control measures, reducing the likelihood and severity of workplace incidents. A thorough risk assessment contributes to a proactive safety culture, demonstrating a commitment to worker well-being and minimizing operational disruptions.

3. Control Measures

Control measures represent a critical component within a safe method work statement template. They constitute the practical actions implemented to mitigate or eliminate the hazards identified during the risk assessment process. The effectiveness of a safe method work statement hinges directly on the selection and implementation of appropriate control measures. These measures should follow the established hierarchy of controls, prioritizing the most effective options.

The hierarchy of controls dictates that the most effective way to control a hazard is to eliminate it entirely. If elimination is not feasible, substitution with a less hazardous alternative should be considered. Engineering controls, such as machine guarding or ventilation systems, offer the next level of protection by physically altering the work environment to reduce risk. Administrative controls, including safe work procedures, training, and signage, modify worker behavior to minimize exposure to hazards. Finally, personal protective equipment (PPE), such as gloves, respirators, and safety glasses, should be used as a last resort or in conjunction with other controls to provide a barrier against hazards. For example, in a scenario involving working at heights, eliminating the need to work at heights is the ideal solution. If not feasible, providing scaffolding (engineering control) and implementing fall arrest procedures (administrative control) in conjunction with harnesses (PPE) presents a multi-layered approach.

A well-defined safe method work statement articulates specific control measures corresponding to each identified hazard. This clarity ensures that all personnel understand the necessary precautions to take while performing the task. Regular review and updates of control measures are essential to maintain their effectiveness and adapt to changing conditions. This might involve incorporating new technologies or adjusting procedures based on lessons learned from incidents or near misses. Challenges in implementing control measures can include cost considerations, resistance to change, and inadequate supervision. Overcoming these challenges requires a commitment to safety, ongoing communication, and appropriate resource allocation.

4. Communication Protocols

Effective communication protocols are essential for ensuring a safe method work statement template translates into practical application and risk reduction. A well-crafted template becomes ineffective if its contents are not properly disseminated and understood by all stakeholders. Communication protocols bridge the gap between documented procedures and on-the-ground execution. This connection ensures everyone involved understands the hazards, risks, and control measures associated with a specific task.

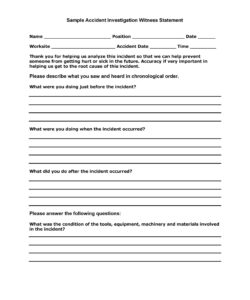

Several key aspects contribute to robust communication protocols within this context. Clear and concise language in the template itself is paramount. Technical jargon should be avoided or clearly defined to ensure universal comprehension. Distribution methods must reach all relevant personnel, utilizing appropriate channels such as email, toolbox talks, or physical postings. Furthermore, verification of understanding is crucial. This could involve quizzes, practical demonstrations, or simply open dialogue to confirm comprehension. For example, a construction site might utilize toolbox talks to discuss specific hazards related to a new excavation, ensuring all workers understand the relevant safety procedures. Similarly, a laboratory setting might employ regular training sessions to reinforce safe handling protocols for hazardous chemicals.

The absence of effective communication can undermine even the most meticulously designed safe method work statement. Misunderstandings or lack of awareness regarding hazards and control measures can lead to incidents and injuries. Conversely, strong communication fosters a safety-conscious culture, empowering workers to identify and mitigate risks proactively. Challenges in communication can include language barriers, varying literacy levels, and reliance on outdated communication methods. Addressing these challenges requires a multi-faceted approach, including translation services, visual aids, and interactive training methods. Ultimately, effective communication protocols ensure that safe method work statements serve their intended purpose: protecting workers and promoting a safe work environment.

5. Training Requirements

Training requirements form an integral link between a safe method work statement template and its practical implementation. A template, however comprehensive, remains a static document until translated into action through properly trained personnel. Training bridges this gap, equipping individuals with the knowledge and skills to execute tasks safely and effectively according to the prescribed procedures. This connection represents a critical component in mitigating workplace hazards and fostering a safety-conscious culture.

Several factors underscore the importance of training within this context. Training ensures comprehension of the safe method work statement’s contents, including hazard identification, risk assessment, and specified control measures. This understanding empowers workers to recognize potential dangers and implement appropriate precautions. Furthermore, training provides opportunities for practical application and skill development. Hands-on exercises, simulations, and real-world scenarios allow individuals to practice the procedures outlined in the template, building confidence and proficiency. For example, workers involved in confined space entry require specialized training on atmospheric monitoring, ventilation procedures, and emergency rescue techniques. Similarly, operators of heavy machinery benefit from comprehensive training on safe operating procedures, pre-use inspections, and emergency shutdown protocols.

Neglecting training requirements can render a safe method work statement ineffective, increasing the risk of incidents and injuries. Untrained personnel may not fully grasp the hazards involved or the necessary precautions, leading to unsafe practices. Conversely, comprehensive training programs enhance worker competence, improve safety performance, and contribute to a proactive safety culture. Addressing potential training challenges, such as language barriers or varying literacy levels, requires tailored approaches like visual aids, interactive modules, and on-site demonstrations. Ultimately, robust training ensures that safe method work statements translate into tangible safety improvements, protecting workers and promoting a safe work environment.

6. Regular Review

Regular review constitutes a crucial element of a robust safe method work statement template. Work environments and operational procedures are not static; they evolve. New equipment is introduced, regulations change, and lessons are learned from experience. Consequently, a safe method work statement requires periodic review and updates to maintain its relevance and effectiveness. This dynamic approach ensures ongoing alignment with current best practices and evolving operational realities.

Several factors underscore the significance of regular review. Technological advancements might necessitate adjustments to procedures or the introduction of new control measures. Changes in legislation or industry standards require corresponding updates to the template to maintain compliance. Furthermore, analyzing incident and near-miss data provides valuable insights into potential weaknesses in existing procedures, prompting necessary revisions. For instance, a manufacturing facility introducing a new robotic system must update its safe method work statements to address the specific hazards associated with the new equipment. Similarly, a construction company might revise its excavation procedures following a near-miss incident involving a utility strike, incorporating lessons learned to prevent future occurrences.

Neglecting regular review can render a safe method work statement outdated and ineffective, increasing the risk of incidents and injuries. Procedures that fail to reflect current hazards or incorporate best practices may not provide adequate protection. Conversely, a commitment to regular review demonstrates a proactive approach to safety management, fostering a culture of continuous improvement and minimizing the potential for operational disruptions. Challenges in implementing regular reviews can include resource constraints and competing priorities. Overcoming these challenges requires integrating the review process into existing management systems, allocating sufficient resources, and emphasizing the long-term benefits of proactive safety management. Ultimately, regular review ensures that safe method work statements remain dynamic tools, adapting to changing circumstances and effectively safeguarding workers.

Key Components of a Safe Method Work Statement Template

A comprehensive template requires careful consideration of several key components to ensure its effectiveness in mitigating workplace hazards.

1. Hazard Identification: This involves a systematic examination of all aspects of a task to identify potential sources of harm, encompassing physical, chemical, ergonomic, and psychosocial hazards.

2. Risk Assessment: Following hazard identification, a risk assessment analyzes the likelihood and potential severity of each hazard. This process prioritizes hazards based on their potential impact.

3. Control Measures: Control measures are actions implemented to mitigate or eliminate identified hazards. These measures should adhere to the hierarchy of controls, prioritizing elimination, substitution, engineering controls, administrative controls, and finally, personal protective equipment.

4. Communication Protocols: Effective communication ensures all personnel understand the hazards, risks, and control measures associated with a task. Clear language, appropriate distribution channels, and verification of understanding are crucial.

5. Training Requirements: Training equips personnel with the knowledge and skills to perform tasks safely according to the defined procedures. Comprehensive training reinforces understanding and promotes competent execution of control measures.

6. Regular Review: Regular review and updates ensure the safe method work statement remains current and effective. This includes incorporating lessons learned, adapting to new technologies, and complying with evolving regulations.

A robust template hinges on the meticulous integration of these components, forming a cohesive approach to hazard mitigation and fostering a proactive safety culture.

How to Create a Safe Method Work Statement Template

Developing a robust template involves a systematic approach encompassing several key stages. Each stage contributes to a comprehensive document that effectively mitigates workplace hazards.

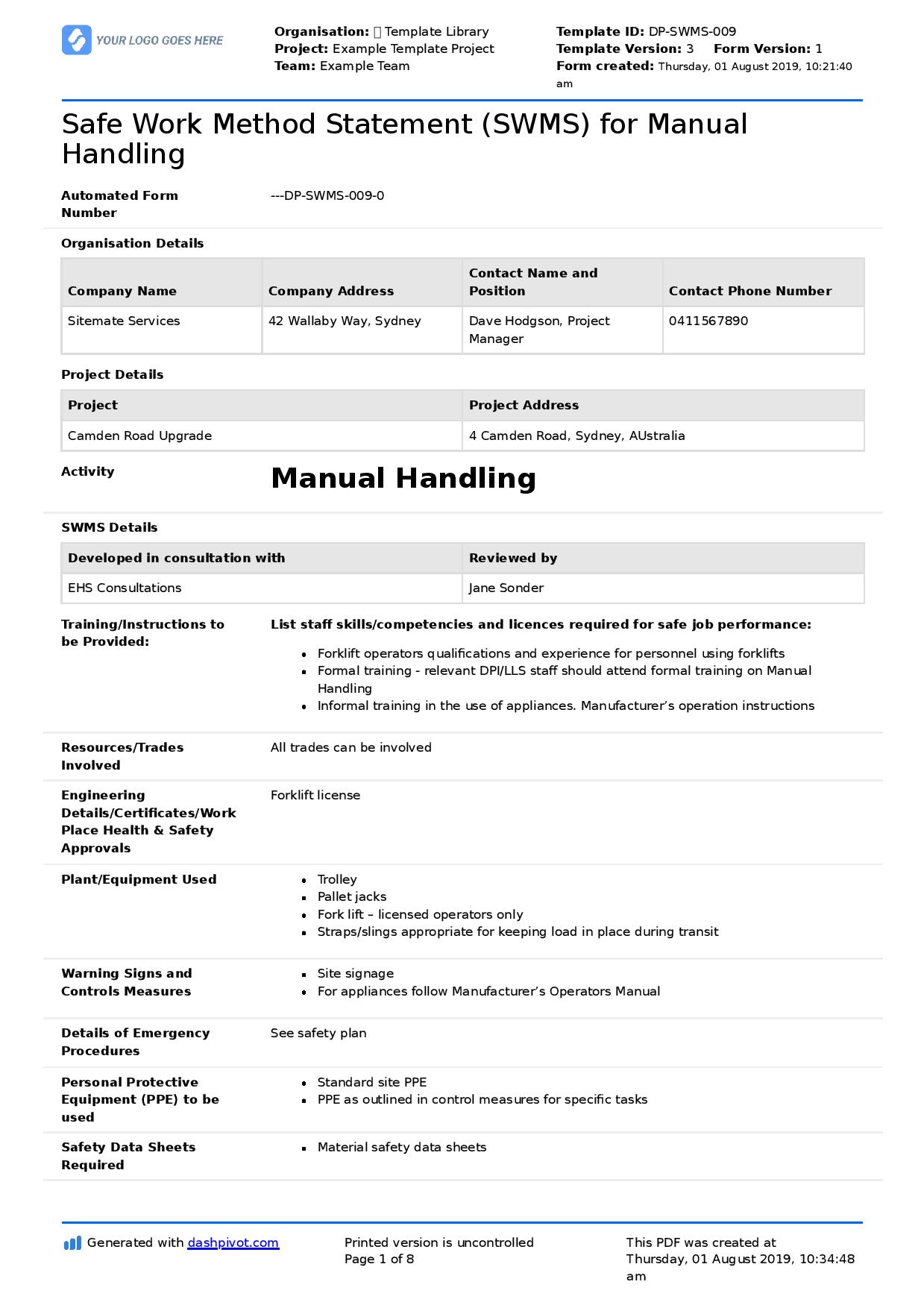

1. Define the Scope: Clearly define the specific task or activity the document will cover. This includes the job location, equipment involved, and personnel responsible. Precise scope ensures the document remains focused and relevant.

2. Conduct a Hazard Identification: Systematically identify all potential hazards associated with the task. Consider physical, chemical, ergonomic, and psychosocial factors. Consult relevant safety data sheets, industry best practices, and experienced personnel.

3. Perform a Risk Assessment: Analyze the likelihood and potential severity of each identified hazard. Utilize a risk matrix to prioritize hazards based on their potential impact.

4. Develop Control Measures: Establish specific control measures for each identified hazard, following the hierarchy of controls. Prioritize elimination, substitution, engineering controls, then administrative controls, with personal protective equipment as a last resort.

5. Establish Communication Protocols: Outline how the safe method work statement will be communicated to all relevant personnel. Ensure clarity, accessibility, and verification of understanding.

6. Define Training Requirements: Specify necessary training for personnel involved in the task, ensuring competency in implementing the control measures and understanding the hazards involved.

7. Implement a Review Process: Establish a schedule for regular review and updates of the safe method work statement. This ensures the document remains current, effective, and aligned with evolving regulations and best practices.

8. Document Everything: Meticulously document all identified hazards, risk assessments, control measures, communication protocols, and training requirements. A well-documented template provides a clear roadmap for safe work practices.

A well-structured template provides a framework for consistent, safe execution of tasks. This proactive approach minimizes workplace incidents, protects personnel, and enhances overall operational efficiency.

Formalized procedures for safe task completion are essential for hazard mitigation in potentially hazardous environments. A structured approach, encompassing hazard identification, risk assessment, control measures, communication protocols, training requirements, and regular review, provides a comprehensive framework for managing workplace risks. Meticulous documentation ensures clarity and consistency in implementation, fostering a safety-conscious culture and minimizing incidents.

Prioritizing robust safety protocols demonstrates a commitment to worker well-being, minimizing operational disruptions, and ensuring regulatory compliance. Proactive risk management, through well-defined procedures, contributes to a safer and more productive work environment. Continual refinement of these procedures, informed by experience and evolving best practices, remains crucial for maintaining a robust safety posture.