Utilizing these pre-planned procedures fosters a proactive safety culture by promoting hazard awareness and encouraging safe work practices. This documentation aids in regulatory compliance and provides evidence of due diligence in managing workplace risks. It facilitates clear communication of safety expectations among workers, supervisors, and contractors, reducing ambiguity and promoting a shared understanding of safe operating procedures. This proactive approach can lead to fewer workplace accidents, lower insurance premiums, and improved overall productivity.

The following sections will delve into the core components of these crucial safety documents, explore best practices for their development and implementation, and provide practical examples across various industries.

1. Hazard Identification

Hazard identification forms the cornerstone of any robust process for ensuring workplace safety. A thorough understanding of potential dangers is crucial for developing effective mitigation strategies within these structured safety plans. Without a comprehensive hazard identification process, subsequent risk assessments and control measures lack a solid foundation, potentially leaving workers vulnerable.

- Physical HazardsPhysical hazards encompass tangible elements within the work environment that can cause harm. Examples include moving machinery, working at heights, exposure to extreme temperatures, or loud noises. Within the structure of these plans, physical hazards must be meticulously identified and documented, specifying their location, nature, and potential impact on worker safety. For instance, a plan for roofing work would explicitly identify fall hazards and the potential for dropped objects.

- Chemical HazardsChemical hazards involve exposure to substances that can cause harm through inhalation, ingestion, or skin contact. These can range from cleaning solutions and solvents to hazardous gases and dusts. Plans must clearly identify all chemicals present in the workplace, including their properties, potential health effects, and safe handling procedures. A laboratory setting, for example, would require detailed identification of specific chemicals and their associated safety data sheets.

- Biological HazardsBiological hazards relate to exposure to harmful biological agents, such as bacteria, viruses, fungi, or parasites. These hazards are common in healthcare settings, laboratories, and agricultural environments. Plans in these contexts necessitate specific identification of potential biological hazards, appropriate personal protective equipment (PPE), and decontamination procedures. A healthcare setting’s plan, for instance, might detail procedures for handling infectious materials and preventing the spread of bloodborne pathogens.

- Ergonomic HazardsErgonomic hazards arise from the interaction between workers and their physical workspace, including factors like posture, repetitive movements, and heavy lifting. These hazards can lead to musculoskeletal disorders and other long-term health problems. Within these safety plans, it is crucial to identify tasks and workstation designs that pose ergonomic risks. For office work, a plan might address proper workstation setup, seating ergonomics, and strategies for minimizing repetitive strain injuries.

By thoroughly addressing each of these hazard categories, these safety plans provide a framework for proactive risk management. This comprehensive approach ensures that all foreseeable dangers are accounted for, leading to more effective control measures and a safer work environment.

2. Risk Assessment

Risk assessment is an integral component of a safe work method statement. It provides a structured approach to evaluating potential hazards identified in the hazard identification phase and determining the level of risk they pose. This process enables informed decisions regarding necessary control measures to mitigate those risks effectively. Without a thorough risk assessment, safety plans lack the necessary depth to prevent incidents and ensure worker well-being.

- LikelihoodLikelihood refers to the probability of a hazardous event occurring. This is assessed based on factors such as the frequency of exposure to the hazard, the work environment, and historical incident data. For example, the likelihood of a fall from a scaffold is higher in wet or windy conditions than in dry, calm weather. Accurately assessing likelihood is critical for prioritizing control measures within the plan.

- SeveritySeverity considers the potential consequences if a hazardous event occurs. This ranges from minor injuries to fatalities, and also includes potential environmental damage or property loss. For instance, the severity of a fall from a height is significantly greater than the severity of a trip on a flat surface. The severity assessment helps determine the level of control measures necessary to reduce the risk to an acceptable level.

- Risk LevelThe risk level combines the likelihood and severity assessments. A high likelihood combined with high severity results in a high-risk level, requiring immediate and comprehensive control measures. A low likelihood and low severity result in a low-risk level, potentially requiring less stringent controls. Within a safe work method statement, clearly defined risk levels guide the implementation of appropriate safety precautions. A confined space entry, for example, typically presents a high-risk level due to the potential for asphyxiation or exposure to hazardous substances.

- Control MeasuresRisk assessments inform the selection and implementation of control measures within the safe work method statement. These controls aim to eliminate or reduce risks to an acceptable level. The hierarchy of control measures prioritizes elimination, substitution, engineering controls, administrative controls, and finally, personal protective equipment (PPE). A risk assessment for working with hazardous chemicals, for instance, might recommend substituting a less hazardous chemical (substitution), installing local exhaust ventilation (engineering control), implementing safe handling procedures (administrative control), and requiring the use of gloves and respirators (PPE).

By systematically evaluating likelihood, severity, and resultant risk levels, the safe work method statement provides a robust framework for prioritizing and implementing effective control measures, ensuring a safer work environment and minimizing the potential for incidents.

3. Control Measures

Control measures represent the practical application of risk mitigation within a safe work method statement template. They translate the theoretical identification and assessment of hazards into actionable steps that directly reduce or eliminate risks. A well-defined template necessitates a comprehensive hierarchy of control measures to ensure worker safety and regulatory compliance. This hierarchy prioritizes the most effective controls, starting with elimination and progressing to less effective measures like personal protective equipment (PPE) as a last resort.

Elimination, the most effective control, removes the hazard entirely. For example, if a task involves working at height, eliminating the need to work at height altogether is the ideal solution. If elimination isn’t feasible, substitution replaces the hazard with a less hazardous alternative. Using a less toxic chemical in a manufacturing process exemplifies substitution. Engineering controls isolate people from hazards through physical modifications. Installing guarding on machinery or implementing ventilation systems to remove hazardous fumes are examples of engineering controls. Administrative controls modify the way work is done to reduce exposure to hazards. Implementing safe work procedures, providing training, or rotating workers to minimize exposure time are examples of administrative controls. PPE, the least effective control, provides a barrier between the worker and the hazard. Examples include safety glasses, gloves, and respirators. While PPE is crucial, it should be considered only after other control measures have been explored and implemented.

Effectively implementing control measures requires clear documentation within the safe work method statement template. This documentation should specify the type of control, its implementation method, the responsible parties, and the required maintenance or inspection schedules. For instance, a template for confined space entry should detail specific control measures such as atmospheric testing, ventilation procedures, and rescue plans. Furthermore, ongoing monitoring and review of control measures are essential to ensure their continued effectiveness and adaptability to changing work conditions. Regular inspections, incident investigations, and feedback from workers contribute to the ongoing improvement of control measures within the template, fostering a robust safety culture and minimizing the likelihood of workplace incidents.

4. Emergency Procedures

Emergency procedures are a critical component of any safe work method statement template. These procedures provide a pre-planned response to foreseeable emergencies, minimizing potential harm to personnel, the environment, and property. A well-defined emergency response plan, integrated within the template, transforms reactive crisis management into proactive mitigation, ensuring a more controlled and effective response when incidents occur. This connection between emergency procedures and the template is essential for establishing a robust safety framework.

The inclusion of emergency procedures directly addresses the potential consequences identified during the risk assessment phase of template development. For instance, if a risk assessment identifies the potential for a chemical spill, the corresponding emergency procedure within the template would detail the necessary steps for containment, cleanup, and decontamination. This direct link ensures that potential incidents are not only identified but also met with pre-determined actions, minimizing the impact of unforeseen events. Another example could be a template for working at heights, which would include emergency procedures for rescuing a worker who has fallen or become suspended from their safety harness. The effectiveness of these procedures relies heavily on regular drills and training, transforming theoretical knowledge into practical, life-saving skills.

A comprehensive safe work method statement template must contain emergency procedures tailored to the specific hazards present in the work environment. These procedures should clearly outline evacuation routes, assembly points, first aid provisions, and contact information for emergency services. Regular review and updates of these procedures are essential to ensure they remain relevant and effective. Challenges may include ensuring all personnel are familiar with the procedures, particularly in dynamic work environments with changing personnel. Addressing these challenges through regular communication, training, and drills strengthens the connection between emergency procedures and the safe work method statement template, fostering a culture of preparedness and enhancing overall workplace safety.

5. Documentation and Review

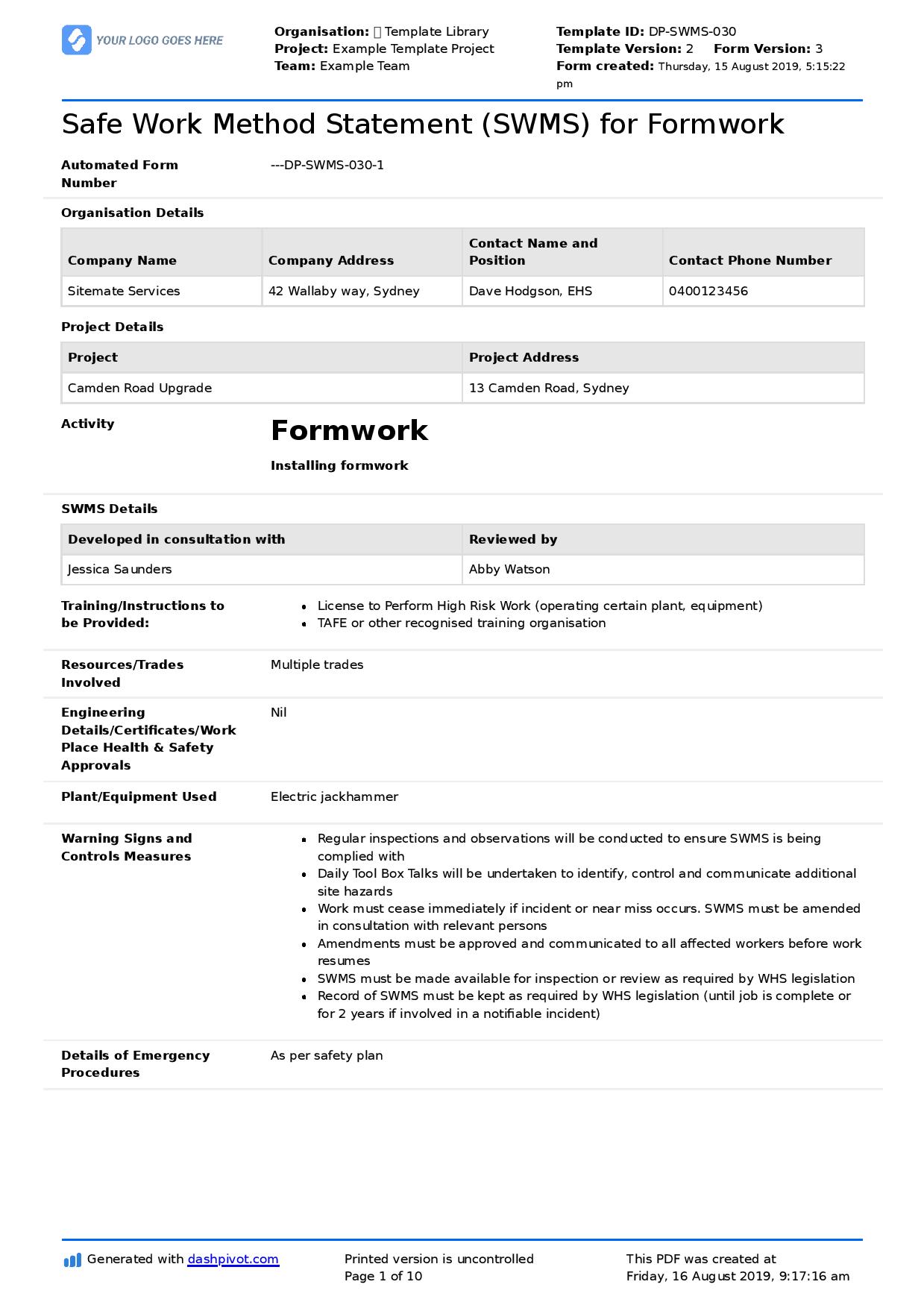

Documentation and review form the backbone of a robust and effective safe work method statement (SWMS) template. Thorough documentation ensures that all identified hazards, assessed risks, and implemented control measures are clearly recorded and readily accessible. This detailed record provides a crucial reference for workers, supervisors, and regulatory bodies, promoting transparency and accountability in safety management. Moreover, meticulous documentation facilitates consistent application of the SWMS, minimizing deviations from established safe work practices. For instance, a well-documented SWMS for confined space entry would include detailed procedures for atmospheric testing, ventilation, and emergency rescue, ensuring that these critical steps are followed consistently every time the confined space is entered.

Regular review of the SWMS template is equally vital. Work environments and associated hazards are dynamic; changes in processes, equipment, or regulations necessitate periodic review and updates to the SWMS. This iterative process ensures the template remains relevant and effective in mitigating evolving risks. Furthermore, incorporating feedback from workers, supervisors, and safety professionals during the review process enhances the practical applicability and overall effectiveness of the SWMS. For example, after a near-miss incident during a lifting operation, a review of the corresponding SWMS might reveal inadequacies in the documented lifting procedures. Revising the SWMS based on this feedback would strengthen the safety protocols and reduce the likelihood of future incidents. Regular review also aids in identifying areas where further training or resources may be required to ensure ongoing compliance with the SWMS.

Effective documentation and review contribute significantly to a proactive safety culture, ensuring continuous improvement in hazard identification, risk assessment, and control implementation. Challenges in maintaining rigorous documentation and review processes may arise from factors such as time constraints, changing work priorities, or inadequate training. Overcoming these challenges requires a commitment to prioritizing safety, allocating sufficient resources for documentation and review, and fostering a culture of continuous improvement. The practical significance of robust documentation and review within a SWMS template cannot be overstated; it forms the foundation for a safe and productive work environment, minimizing the likelihood of incidents and promoting the well-being of all stakeholders.

Key Components of a Safe Work Method Statement Template

A comprehensive template ensures consistent and effective hazard management. Several key components contribute to its efficacy.

1. Scope and Applicability: Clearly defines the specific task, location, and personnel to which the document applies. This clarifies the boundaries of the procedure and ensures relevant hazard identification.

2. Hazard Identification: Systematically identifies all foreseeable hazards associated with the task, encompassing physical, chemical, biological, and ergonomic risks. Thorough identification forms the basis for subsequent risk assessment and control measures.

3. Risk Assessment: Evaluates the likelihood and potential severity of each identified hazard, determining the overall risk level. This process prioritizes hazards and informs the selection of appropriate control measures.

4. Control Measures: Details specific procedures and precautions to eliminate or mitigate identified hazards, following the hierarchy of control measures (elimination, substitution, engineering controls, administrative controls, and personal protective equipment). Clear instructions ensure consistent implementation.

5. Emergency Procedures: Outlines pre-planned responses to foreseeable emergencies, including evacuation procedures, first aid provisions, and contact information for emergency services. Preparedness minimizes potential harm during incidents.

6. Personal Protective Equipment (PPE): Specifies the necessary PPE for each task, ensuring workers have adequate protection against identified hazards. This includes details on proper usage, maintenance, and limitations of PPE.

7. Documentation and Review: Emphasizes the importance of maintaining accurate records of the SWMS, including revisions and updates. Regular review ensures the document remains relevant and effective in addressing evolving risks.

8. Communication and Training: Highlights the need for effective communication of the SWMS to all relevant personnel. Adequate training ensures workers understand and can implement the procedures outlined in the document.

These elements working in concert create a comprehensive framework for managing workplace safety, facilitating proactive hazard mitigation and fostering a culture of safety consciousness.

How to Create a Safe Work Method Statement Template

Creating a robust template requires a systematic approach, ensuring comprehensive consideration of potential hazards and effective control measures. The following steps outline a structured process for developing and implementing a template.

1. Define Scope and Applicability: Clearly specify the task, location, and personnel covered by the template. Precise definition ensures relevant hazard identification and appropriate control measures. For example, a template for welding operations should clearly state the specific welding processes, the designated work area, and the qualifications required for personnel involved.

2. Conduct a Thorough Hazard Identification: Systematically identify all foreseeable hazards associated with the task, encompassing physical, chemical, biological, and ergonomic risks. Consult relevant safety data sheets, industry best practices, and experienced personnel. This comprehensive approach ensures no potential hazard is overlooked.

3. Assess Risks: Evaluate the likelihood and potential severity of each identified hazard. Utilize a risk matrix or similar tool to determine the overall risk level. This assessment informs the prioritization of control measures.

4. Determine Control Measures: Implement control measures following the hierarchy of controls, prioritizing elimination, substitution, engineering controls, administrative controls, and lastly, personal protective equipment (PPE). Clearly document each control measure, specifying its implementation, responsible parties, and monitoring procedures.

5. Develop Emergency Procedures: Outline clear and concise emergency procedures for foreseeable incidents. Include evacuation routes, assembly points, first aid protocols, and contact information for emergency services. Ensure regular drills and training are conducted to familiarize personnel with these procedures.

6. Specify Required PPE: Detail the necessary PPE for each task, ensuring it provides adequate protection against identified hazards. Include information on proper usage, maintenance, and limitations of the PPE. Regular inspection and replacement of PPE are crucial.

7. Document and Review: Maintain comprehensive documentation of the template, including all identified hazards, risk assessments, and control measures. Establish a regular review schedule, incorporating feedback from workers, supervisors, and safety professionals. This ensures the template remains current and effective.

8. Communicate and Train: Effectively communicate the template to all relevant personnel. Provide comprehensive training to ensure workers understand and can competently implement the procedures outlined in the document. Ongoing communication and refresher training reinforce safe work practices.

A well-defined template, implemented through a systematic process, establishes a robust framework for managing workplace safety, fostering a proactive approach to hazard mitigation, and promoting a culture of continuous improvement. This commitment to safety enhances worker well-being and contributes to a more productive work environment.

Formalized procedures for documenting job hazards and outlining necessary controls are essential for ensuring workplace safety. These structured documents provide a systematic approach to hazard identification, risk assessment, and the implementation of effective control measures. A comprehensive template includes details on emergency procedures, required personal protective equipment, and procedures for documentation and review. Effective communication and training on these procedures are critical for their successful implementation.

Prioritizing the development and implementation of these detailed safety plans demonstrates a commitment to proactive risk management. This proactive approach fosters a safety-conscious work environment, minimizing incidents, protecting workers, and enhancing overall productivity. Continual refinement of these procedures, based on feedback and evolving best practices, remains crucial for maintaining a robust safety culture and adapting to dynamic workplace conditions.