Implementing such documented procedures fosters a proactive safety culture, reducing the likelihood of accidents and injuries. This, in turn, can lead to decreased downtime, improved productivity, and enhanced compliance with relevant safety regulations. A well-defined process also contributes to better communication and understanding of potential risks amongst all stakeholders involved in a project.

Further exploration will delve into the key components of these essential safety documents, offering practical guidance on their development and implementation. Subsequent sections will address topics such as hazard identification, risk assessment, control measures, and emergency procedures, providing a comprehensive overview of how to establish and maintain a safe working environment.

1. Hazard Identification

Hazard identification forms the cornerstone of a robust safe working method statement. Without a thorough understanding of the potential dangers inherent in a task, effective control measures cannot be implemented. This process involves systematically examining all aspects of the work activity to identify anything that could cause harm, including physical, chemical, biological, ergonomic, and psychosocial hazards. A comprehensive hazard identification process considers the work environment, equipment used, materials handled, and the individuals involved. For example, in a laboratory setting, hazards might include chemical spills, exposure to pathogens, or the use of specialized equipment.

The identified hazards are then documented within the method statement, providing a clear picture of the risks associated with the task. This documentation facilitates the subsequent risk assessment process, where the likelihood and potential severity of each hazard are evaluated. This, in turn, informs the selection and implementation of appropriate control measures. For instance, if a hazard analysis for operating heavy machinery identifies a risk of crushing injuries, corresponding control measures might include implementing lockout/tagout procedures and ensuring adequate operator training. Failing to identify hazards at this initial stage can have significant consequences, leading to inadequate safety precautions and increased risk of incidents.

Effective hazard identification requires a multi-faceted approach, often involving consultation with workers, supervisors, safety professionals, and relevant regulatory guidance. Checklists, site inspections, and task analysis are valuable tools in this process. Ultimately, the comprehensiveness of hazard identification directly impacts the overall effectiveness of the safe working method statement and its ability to protect workers and ensure a safe working environment. Challenges may arise in identifying less obvious hazards, such as psychosocial risks or those associated with non-routine tasks. Therefore, continuous monitoring, review, and adaptation of the method statement are crucial for maintaining a robust safety management system.

2. Risk Assessment

Risk assessment is integral to a safe working method statement template. It provides a structured approach to evaluating the potential harm from identified hazards, considering both the likelihood of occurrence and the severity of potential consequences. This evaluation allows for prioritization of control measures, focusing resources on the most significant risks. A robust risk assessment process ensures the chosen safety precautions are proportionate to the potential harm, avoiding both excessive and inadequate safety measures. For example, working at heights on a construction site presents a high risk of falls, requiring robust control measures like scaffolding and fall arrest systems, while a low-risk task, such as desk work, might only require ergonomic assessments and appropriate workstation setup.

The risk assessment process typically involves assigning a risk rating to each identified hazard. This is often achieved through a matrix that considers both likelihood and severity. The resulting risk rating informs the selection and implementation of control measures. High-risk activities necessitate stringent controls, while lower-risk activities may require less intensive measures. This structured approach ensures resources are allocated effectively, optimizing safety efforts. For instance, confined space entry, a high-risk activity, mandates comprehensive procedures, including atmospheric monitoring, emergency rescue plans, and specialized training, whereas a low-risk activity like using a computer may only require basic safety training and regular breaks.

The documented risk assessment becomes a critical component of the safe working method statement. It provides a clear justification for the chosen control measures and demonstrates a commitment to proactive safety management. This documentation also facilitates communication among stakeholders, ensuring everyone involved understands the potential risks and the measures in place to mitigate them. Regular review and updates of the risk assessment are essential to account for changing conditions, new information, or lessons learned from previous incidents. Challenges in risk assessment may arise from accurately estimating the likelihood and severity of hazards, particularly those with low probability but high potential consequences. Therefore, maintaining a comprehensive risk assessment process is vital for the ongoing effectiveness of the safe working method statement.

3. Control Measures

Control measures represent the practical application of risk mitigation within a safe working method statement. They translate the theoretical assessment of hazards into actionable steps designed to minimize or eliminate risks. A comprehensive suite of control measures is crucial for ensuring the effectiveness of the method statement and protecting worker safety. These measures form the core of the safe system of work outlined in the document, providing specific guidance on how to execute tasks safely.

- EliminationElimination represents the most effective control measure, entirely removing the hazard from the workplace. This might involve substituting hazardous materials with safer alternatives, automating dangerous processes, or redesigning work areas to prevent hazards. For instance, eliminating the need for manual lifting by using mechanical lifting equipment entirely removes the risk of manual handling injuries. While highly effective, elimination is not always feasible.

- SubstitutionWhen elimination is not possible, substitution offers the next level of control. This involves replacing a hazardous material, process, or piece of equipment with a less hazardous option. For example, substituting a highly flammable solvent with a less flammable alternative reduces the fire risk. Substitution, while effective, requires careful consideration of the replacement’s potential hazards to ensure it does not introduce new risks.

- Engineering ControlsEngineering controls involve physical modifications to the workplace, equipment, or processes to minimize hazard exposure. These controls include machine guarding, ventilation systems, safety interlocks, and noise barriers. For example, installing local exhaust ventilation to remove airborne contaminants protects workers from inhalation hazards. Engineering controls provide a more reliable level of protection than administrative controls or personal protective equipment.

- Administrative ControlsAdministrative controls rely on procedures and work practices to reduce risk. Examples include safe work procedures, training programs, job rotation, and signage. For instance, implementing a lockout/tagout procedure for machinery maintenance prevents accidental startup and associated injuries. Administrative controls require diligent implementation and monitoring to remain effective, as they rely on consistent adherence to procedures.

The hierarchy of control measures emphasizes implementing the most effective controls first, progressing down the hierarchy only when higher-level controls are not feasible. Safe working method statements should clearly detail the specific control measures for each identified hazard, ensuring a comprehensive and robust approach to safety management. Regular review and adaptation of these controls are essential to maintain their effectiveness and address any emerging risks or changes in the work environment. Combining multiple control measures often provides the most robust approach to risk mitigation.

4. Emergency Procedures

Emergency procedures constitute a critical component of any robust safe working method statement template. They provide pre-planned, step-by-step instructions for managing foreseeable emergencies, minimizing potential harm to personnel, the environment, and property. The inclusion of well-defined emergency procedures demonstrates a proactive approach to safety management, ensuring a swift and effective response to unforeseen incidents. This preparedness reduces the likelihood of panic and confusion during emergencies, facilitating a more controlled and efficient response. For example, a method statement for welding operations might include procedures for handling fire outbreaks, gas leaks, and electric shocks, specifying actions such as activating fire alarms, evacuating the area, and administering first aid.

A strong connection exists between the identified hazards and the development of appropriate emergency procedures. Each identified hazard should have a corresponding emergency procedure outlined within the method statement. This ensures specific risks are addressed with tailored responses, optimizing the effectiveness of emergency actions. For instance, a chemical spill requires a different emergency response than a fire, necessitating distinct procedures for containment, cleanup, and decontamination. Clearly documented procedures, readily accessible to all personnel, are essential. This accessibility ensures everyone understands their roles and responsibilities during an emergency, facilitating a coordinated and effective response. Regular drills and training exercises reinforce these procedures, enhancing familiarity and preparedness.

Integration of emergency procedures within the safe working method statement reinforces a comprehensive approach to safety management. It bridges the gap between hazard identification and practical risk mitigation, ensuring a cohesive and effective safety strategy. Challenges may arise in anticipating all potential emergencies or ensuring consistent adherence to procedures during high-stress situations. Therefore, regular review, refinement, and practice of emergency procedures are vital for maintaining a state of preparedness and ensuring the ongoing effectiveness of the safe working method statement. This proactive approach minimizes the impact of unforeseen events and fosters a culture of safety and preparedness within the workplace.

5. Competent Personnel

A safe working method statement template, while comprehensive, remains ineffective without competent personnel to interpret, implement, and uphold its guidelines. Personnel competency forms the bedrock of practical safety application, bridging the gap between documented procedures and real-world execution. This section explores the multifaceted connection between competent personnel and effective implementation of safe working method statements.

- Training and QualificationsAdequate training equips personnel with the knowledge and skills necessary to understand and execute the method statement’s requirements. Formal qualifications validate this competency, ensuring personnel possess the necessary theoretical and practical understanding of relevant safety regulations and procedures. For example, a worker operating heavy machinery must have appropriate certifications and training to operate the equipment safely, as outlined in the method statement. Lack of proper training can lead to misinterpretation of procedures, increasing the risk of incidents.

- Experience and FamiliarityPractical experience allows personnel to apply theoretical knowledge in real-world scenarios, anticipating potential challenges and adapting to dynamic work environments. Familiarity with the specific task and the associated hazards, fostered through experience, enhances risk perception and promotes proactive safety behavior. A seasoned electrician, for example, is more likely to recognize and address potential electrical hazards than a novice, even when both have access to the same method statement.

- Communication and TeamworkEffective communication ensures all personnel understand and adhere to the method statement’s guidelines. Open communication channels facilitate the sharing of safety concerns, observations, and near-miss reports, promoting continuous improvement of safety practices. Teamwork fosters a shared responsibility for safety, ensuring collective adherence to the method statement and creating a supportive safety culture. For instance, clear communication between a crane operator and rigger is crucial for safe lifting operations, as outlined in the lifting plan, a specialized form of a method statement.

- Supervision and OversightCompetent supervision ensures adherence to the method statement’s provisions. Effective supervisors monitor work activities, provide guidance, and address safety concerns promptly. Regular oversight reinforces the importance of adhering to the method statement and provides opportunities for feedback and improvement. A construction site supervisor, for example, plays a critical role in ensuring workers comply with the method statement for excavation work, mitigating the risks of cave-ins.

The interplay of these facets highlights the crucial role competent personnel play in translating a safe working method statement template into a practical instrument of safety. Without competent individuals to implement and uphold its guidelines, even the most comprehensive method statement remains a paper exercise. Investing in training, fostering experience, promoting communication, and providing effective supervision maximizes the effectiveness of safe working method statements, fostering a strong safety culture and minimizing workplace risks. The absence of competent personnel undermines the entire safety management system, rendering the method statement largely ineffective and increasing the likelihood of incidents.

6. Regular Review

Regular review constitutes a critical, dynamic component of a safe working method statement template. Its importance stems from the evolving nature of work environments, where new hazards may emerge, and existing controls may become less effective over time. This continuous evaluation process ensures the method statement remains a relevant and robust tool for managing workplace risks. Regular review cycles prevent the document from becoming static and outdated, maintaining its alignment with current conditions and best practices. For example, a construction site method statement might require review after the introduction of new equipment or following a near-miss incident, allowing for necessary adjustments to procedures and controls.

The practical significance of regular review manifests in several ways. Firstly, it allows for the identification and mitigation of emerging hazards before they escalate into incidents. Secondly, it provides an opportunity to incorporate lessons learned from previous incidents or near misses, strengthening preventative measures. Thirdly, it ensures compliance with evolving regulatory requirements and industry best practices. Finally, it demonstrates a commitment to continuous improvement in safety management, fostering a proactive safety culture. A manufacturing facility, for instance, might revise its method statement for chemical handling after a minor spill, incorporating improved containment measures and enhanced training protocols based on the incident investigation findings. Without regular review, the method statement risks becoming a static document, failing to address evolving risks and potentially contributing to incidents.

Several factors influence the frequency and scope of reviews. The inherent risk level of the task, the frequency of task execution, and any changes in the work environment all necessitate adjustments to the review schedule. High-risk activities and frequently performed tasks typically require more frequent reviews. Similarly, significant changes in work processes, equipment, or personnel necessitate prompt review and revision of the method statement. Challenges may arise in maintaining consistent review schedules and ensuring adequate resources for thorough evaluations. However, overcoming these challenges through dedicated planning and resource allocation is crucial for maintaining the efficacy of the safe working method statement as a dynamic tool for managing workplace safety. Regular review, therefore, forms an integral part of a robust safety management system, ensuring the ongoing relevance and effectiveness of the method statement in protecting workers and preventing incidents.

Key Components of a Safe Working Method Statement

A comprehensive safe working method statement requires careful consideration of several key components to ensure its effectiveness in mitigating workplace risks. These components work together to provide a structured approach to hazard identification, risk assessment, and implementation of control measures. Omitting any of these elements can compromise the overall integrity and effectiveness of the method statement.

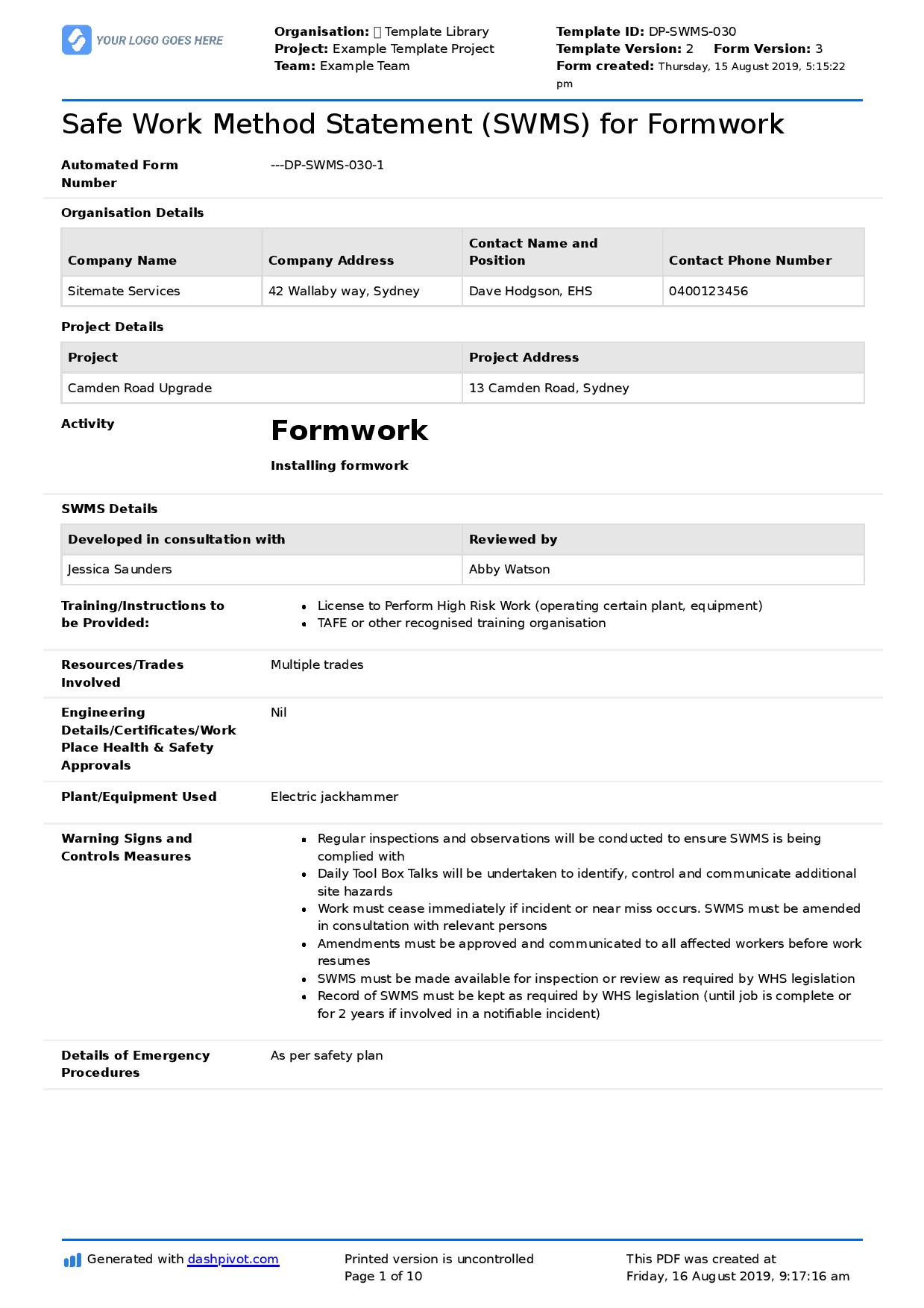

1. Task Description: A clear and concise description of the task to be performed is fundamental. This includes the scope of work, location, equipment involved, and the anticipated duration. A well-defined task description sets the context for subsequent hazard identification and risk assessment.

2. Hazard Identification: This component involves systematically identifying all potential hazards associated with the task. This includes considering physical, chemical, biological, ergonomic, and psychosocial hazards. A thorough hazard identification process forms the basis for effective risk mitigation.

3. Risk Assessment: Following hazard identification, a risk assessment evaluates the likelihood and potential severity of each identified hazard. This assessment typically uses a risk matrix to assign a risk rating, which informs the selection and implementation of appropriate control measures.

4. Control Measures: Control measures represent the practical steps taken to eliminate or minimize identified risks. These measures follow the hierarchy of controls, prioritizing elimination, substitution, engineering controls, administrative controls, and finally, personal protective equipment.

5. Emergency Procedures: This component outlines the procedures to be followed in the event of foreseeable emergencies. These procedures provide step-by-step instructions for managing incidents, minimizing potential harm to personnel, the environment, and property.

6. Personal Protective Equipment (PPE): When other control measures cannot adequately mitigate risks, PPE provides a last line of defense. The method statement specifies the required PPE, ensuring its proper selection, use, maintenance, and storage.

7. Competent Personnel: The method statement must clearly identify the required competencies for personnel involved in the task. This includes necessary training, qualifications, experience, and communication skills. Ensuring competent personnel is crucial for effective implementation of the method statement.

8. Monitoring and Review: A process for monitoring the effectiveness of the method statement and conducting regular reviews is essential. This allows for adjustments based on changing conditions, lessons learned from incidents, and evolving best practices. Continuous improvement ensures ongoing effectiveness of the method statement.

A method statements efficacy hinges on these interconnected components. Each element contributes to a structured and systematic approach to managing workplace safety. This comprehensive approach reduces risks, protects personnel, and fosters a proactive safety culture.

How to Create a Safe Working Method Statement

Developing a robust safe working method statement requires a systematic approach encompassing several key stages. Each stage contributes to the overall effectiveness of the document in mitigating workplace hazards and fostering a safe working environment. The following steps provide a practical guide to creating a comprehensive and effective method statement.

1. Define the Scope: Clearly define the task or activity the method statement will cover. This includes specifying the work location, equipment involved, personnel responsible, and the anticipated duration. A precise scope ensures the method statement remains focused and relevant to the specific task.

2. Conduct a Hazard Identification: Systematically identify all foreseeable hazards associated with the defined scope. This involves considering potential physical, chemical, biological, ergonomic, and psychosocial hazards. Consult relevant regulations, industry best practices, and involve workers with practical experience in the task for a comprehensive hazard identification.

3. Assess the Risks: Evaluate the likelihood and potential severity of each identified hazard. Utilize a risk matrix to assign a risk rating based on the likelihood of occurrence and the potential consequences. This structured approach facilitates prioritization of control measures.

4. Implement Control Measures: Determine and document appropriate control measures for each identified hazard, following the hierarchy of controls. Prioritize elimination, substitution, engineering controls, and administrative controls. Specify any necessary personal protective equipment (PPE) as a last resort when other controls are not feasible or sufficient.

5. Develop Emergency Procedures: Outline clear, step-by-step procedures for foreseeable emergencies related to the identified hazards. Include instructions for evacuation, first aid, spill containment, and other relevant emergency responses. Ensure these procedures are readily accessible to all personnel involved in the task.

6. Define Competency Requirements: Specify the required training, qualifications, and experience for personnel involved in the task. Ensure all personnel possess the necessary competencies to understand and implement the method statement effectively. Provide adequate training and supervision to maintain competency levels.

7. Document and Communicate: Document all the above information in a clear, concise, and accessible format. Communicate the method statement to all relevant personnel, ensuring they understand its contents and their responsibilities. Provide opportunities for feedback and clarification.

8. Monitor, Review, and Update: Implement a system for monitoring the effectiveness of the method statement and conducting regular reviews. Update the method statement to reflect changes in work processes, new hazards, lessons learned from incidents, or evolving best practices. Regular review ensures the document remains relevant and effective in mitigating risks.

A robust method statement provides a framework for managing workplace hazards. By following these steps, organizations can develop comprehensive safe working method statements that contribute to a safer and healthier work environment, minimizing risks, and promoting a culture of safety. Adherence to these guidelines enhances workplace safety by providing a proactive approach to hazard management and facilitating continuous improvement in safety performance.

Documented procedures for safe work practices provide a crucial foundation for a robust safety management system. These structured approaches to hazard identification, risk assessment, and control implementation are essential for minimizing workplace risks and fostering a proactive safety culture. From defining the scope of work and outlining emergency procedures to specifying competency requirements and ensuring regular review, each component contributes to a comprehensive strategy for protecting personnel and preventing incidents. The information provided here offers practical guidance for developing and implementing these critical safety documents, promoting a more informed and proactive approach to workplace safety.

Effective management of workplace safety requires a commitment to continuous improvement and adaptation. As work environments evolve and new challenges emerge, the principles discussed herein provide a framework for maintaining a dynamic approach to hazard mitigation. Prioritizing safety through well-defined procedures fosters a culture of responsibility and preparedness, contributing significantly to a safer and more productive work environment. Ultimately, the diligent application of these principles serves as a cornerstone for minimizing risks, protecting personnel, and fostering a culture of safety in any workplace.