Utilizing a pre-designed structure for these documents offers several advantages. It promotes consistency in safety procedures across different projects and teams. A clear and concise format improves communication and understanding of the risks involved, empowering workers to take ownership of their safety. Documentation of hazard identification and control measures also demonstrates a commitment to legal compliance and best practices, potentially reducing liability and insurance costs. Furthermore, it facilitates effective supervision and monitoring of work activities, enabling proactive intervention to prevent incidents.

This discussion will further explore the essential components, creation process, and practical implementation of these vital safety documents, emphasizing their role in fostering a safe and productive work environment.

1. Hazard Identification

Hazard identification forms the cornerstone of a robust work safe method statement. A comprehensive understanding of potential dangers is crucial for developing effective control measures and ensuring worker safety. This process involves systematically examining all aspects of a task to pinpoint potential sources of harm.

- Types of Hazards:Hazards encompass a wide range of potential sources of harm, categorized as physical, chemical, biological, ergonomic, and psychosocial. Physical hazards include working at height, moving machinery, and electricity. Chemical hazards involve exposure to hazardous substances. Biological hazards include exposure to bacteria or viruses. Ergonomic hazards relate to workstation design and repetitive tasks. Psychosocial hazards involve factors like stress, workload, and workplace violence. Accurately categorizing hazards within a method statement allows for targeted control measures.

- Risk Assessment:Hazard identification is intrinsically linked to risk assessment. Once a hazard is identified, its potential impact and likelihood of occurrence must be evaluated. This involves considering factors like the severity of potential injuries, the number of workers exposed, and the frequency of exposure. This assessment informs the selection and prioritization of appropriate control measures within the method statement.

- Consultation and Communication:Effective hazard identification requires consultation with workers who possess valuable practical knowledge and experience. Their input can help identify potential hazards that might be overlooked by those less familiar with the task. Clear communication of identified hazards to all involved personnel is essential for ensuring shared understanding and promoting safe work practices. This shared understanding is documented in the method statement.

- Review and Update:Hazard identification is not a static process. Work environments and tasks can change, introducing new hazards or altering existing ones. Regular reviews of the method statement, particularly after incidents or near misses, are crucial for ensuring it remains current and relevant. This iterative process ensures continuous improvement in safety management.

By thoroughly identifying and analyzing potential hazards, a work safe method statement facilitates the development of comprehensive control measures, fostering a proactive approach to safety management and minimizing the risk of workplace incidents. A well-defined hazard identification process ultimately contributes to a safer and more productive work environment.

2. Control Measures

Control measures are the core of a work safe method statement template, translating hazard identification into actionable steps for risk mitigation. They represent the practical application of safety principles, outlining specific actions and procedures designed to minimize or eliminate identified hazards. Effectively implemented control measures are crucial for creating a safe and productive work environment.

- Hierarchy of Controls:Control measures are typically selected and implemented according to the hierarchy of controls, a system that prioritizes the most effective methods for hazard control. Elimination, the most effective approach, removes the hazard entirely. Substitution replaces the hazard with a less hazardous alternative. Engineering controls isolate people from the hazard through physical modifications. Administrative controls modify the way work is done, such as implementing safe work procedures. Personal protective equipment (PPE), the last line of defense, provides a barrier between the worker and the hazard. A method statement should clearly outline the selected controls and justify their placement within the hierarchy.

- Specificity and Practicality:Control measures within a method statement must be specific and practical. Vague or generalized statements are ineffective. For instance, instead of stating “use appropriate safety equipment,” the method statement should specify the exact type of PPE required, such as “wear safety glasses conforming to ANSI Z87.1.” This level of detail ensures clarity and facilitates proper implementation.

- Monitoring and Enforcement:The effectiveness of control measures depends on consistent monitoring and enforcement. A method statement should outline procedures for monitoring the implementation of controls and ensuring compliance. This may include regular inspections, toolbox talks, and supervisory oversight. Clear consequences for non-compliance should also be established and communicated.

- Review and Adaptation:Control measures are not static; they must be reviewed and adapted as needed. Changes in work processes, new information about hazards, or incidents and near misses can necessitate revisions to the control measures within a method statement. Regular reviews and updates ensure the continued effectiveness of the safety plan.

By outlining specific, practical, and enforceable control measures, a work safe method statement provides a roadmap for managing workplace hazards effectively. This structured approach to risk mitigation is essential for minimizing incidents, protecting workers, and fostering a culture of safety. Regular review and adaptation of control measures, informed by ongoing monitoring and feedback, ensures the continued relevance and effectiveness of the method statement in maintaining a safe work environment.

3. Step-by-step Procedures

Clear and concise step-by-step procedures form the backbone of a work safe method statement template. They translate general safety principles and hazard controls into specific actions, guiding workers through tasks safely and efficiently. These procedures provide a structured approach to work execution, minimizing ambiguity and promoting consistent adherence to safety protocols.

- Clarity and Detail:Procedures must be written in clear, unambiguous language, avoiding jargon or technical terms that could lead to misinterpretation. Each step should be detailed enough to guide workers effectively, leaving no room for guesswork. For example, in a confined space entry procedure, rather than simply stating “test the atmosphere,” the procedure should specify the exact equipment to be used, the acceptable gas readings, and the frequency of testing.

- Sequence and Logic:Steps must be presented in a logical sequence, reflecting the actual order of operations. This ensures that tasks are performed in the correct order, minimizing the risk of errors and incidents. Dependencies between steps should be clearly identified. For instance, in a lifting operation, the procedure would outline steps such as inspecting the lifting equipment before use, securing the load correctly, and communicating with the crane operator throughout the lift.

- Integration with Hazard Controls:Step-by-step procedures directly incorporate the hazard controls identified in the method statement. Each step should reflect the implementation of specific control measures. For example, a procedure for working at height might include steps for setting up and using fall arrest systems, reflecting the control measure of fall protection. This integration ensures that safety is embedded within the work process itself.

- Accessibility and Training:Procedures must be readily accessible to all workers involved in the task. They should be communicated effectively through training sessions, toolbox talks, and readily available documentation. Workers should be trained not only on the procedures themselves but also on the underlying safety principles and the reasons behind each step. This understanding promotes active engagement with safety protocols and reduces the risk of complacency.

Well-defined step-by-step procedures transform a work safe method statement from a theoretical document into a practical tool for managing workplace safety. By providing clear, detailed, and logically sequenced instructions, these procedures empower workers to perform their tasks safely and efficiently, contributing to a culture of safety and minimizing the risk of workplace incidents. Regular review and refinement of procedures, based on feedback from workers and lessons learned from near misses or incidents, ensures their ongoing effectiveness and relevance.

4. Competency Requirements

A work safe method statement template must explicitly define competency requirements. Ensuring personnel possess the necessary skills, knowledge, and experience to execute tasks safely is paramount. Clearly defined competency requirements mitigate risks stemming from inadequate training or insufficient expertise. This section explores the facets of competency and their integration within a method statement.

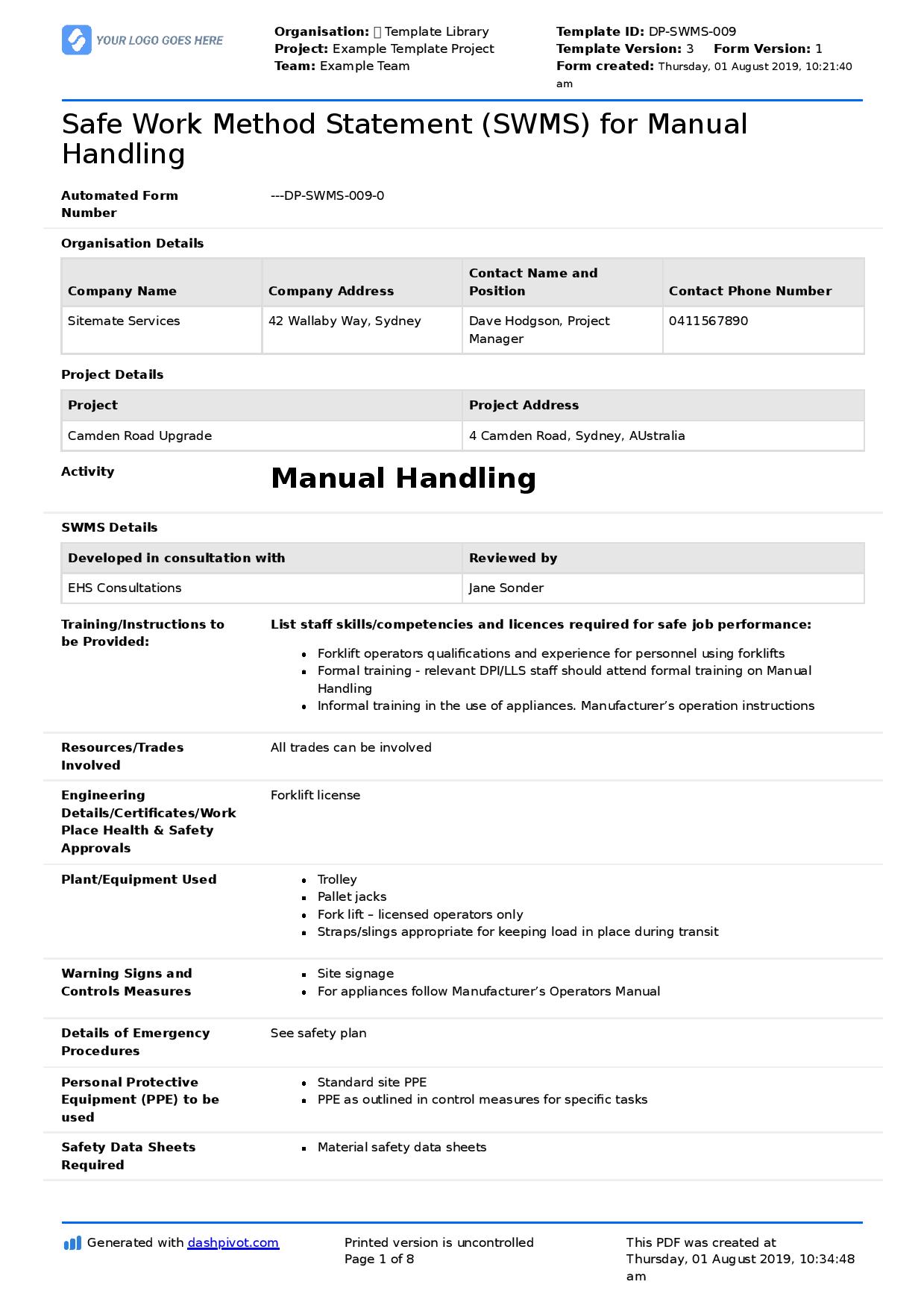

- Documented Training and Qualifications:Method statements should specify required certifications, licenses, and training programs. For example, operating a forklift necessitates a valid forklift operator’s license. Working at height may require documented training in fall protection systems. These stipulations ensure individuals possess verifiable evidence of their competence.

- Experience and Skill Demonstration:Beyond formal qualifications, practical experience is often essential. A method statement might stipulate a minimum number of hours logged performing a specific task or require supervised demonstrations of proficiency. For complex tasks, such as rigging or welding, demonstrable skill is critical for safe execution.

- Refresher Training and Competency Assessment:Competency is not static; skills can deteriorate over time. Method statements should outline requirements for refresher training and periodic competency assessments. This ensures skills remain current and personnel maintain the required level of proficiency. Regular assessments reinforce safe practices and identify areas needing improvement.

- Supervision and Mentoring:For less experienced personnel, a method statement might mandate supervision by a competent individual. Mentorship programs can provide practical guidance and support, fostering skill development and reinforcing safe work practices. This tiered approach ensures adequate oversight and promotes a culture of safety.

By outlining specific competency requirements, the method statement reinforces its commitment to worker safety. This structured approach to competency management minimizes risks associated with inadequate training and experience, contributing to a safer and more productive work environment. Regular review and updates of competency requirements, informed by industry best practices and evolving job demands, ensure the continued relevance and effectiveness of the method statement.

5. Emergency Procedures

Emergency procedures constitute a critical component of a work safe method statement template. They provide a structured response to unforeseen events, mitigating potential harm and ensuring worker safety. A comprehensive method statement anticipates potential emergencies relevant to the specific task and outlines clear steps for action. This preparedness minimizes confusion and facilitates a swift, coordinated response during critical incidents. The connection between emergency procedures and the method statement lies in their shared goal of preventing harm and ensuring a safe working environment. Emergency procedures translate the method statement’s preventative approach into reactive measures, providing a safety net when preventative measures fail or unforeseen circumstances arise.

Consider a welding operation within a confined space. The method statement would outline preventative measures, such as gas testing and ventilation, to minimize the risk of fire or asphyxiation. However, should a fire occur despite these precautions, the emergency procedures within the method statement would dictate actions such as evacuation protocols, emergency contact information, and the location of fire extinguishers. Similarly, in a working-at-height scenario, while fall protection equipment serves as a primary control measure, the method statement’s emergency procedures would address the response to a fall, including rescue procedures and first aid protocols. These examples illustrate the crucial role emergency procedures play in bridging the gap between prevention and response, ensuring worker safety even in unforeseen circumstances.

Effective emergency procedures within a method statement are characterized by clarity, accessibility, and practicality. They should be written in concise language, easily understood by all personnel, and readily available at the worksite. Regular drills and training exercises are crucial for familiarizing workers with these procedures and ensuring a coordinated response in a real emergency. Integrating emergency procedures within the method statement ensures they are considered an integral part of the work planning process rather than an afterthought. This integrated approach reinforces a proactive safety culture, fostering a prepared and responsive workforce equipped to handle emergencies effectively and minimize their impact.

Key Components of a Work Safe Method Statement

A comprehensive work safe method statement requires several key components to effectively manage workplace hazards and ensure worker safety. These components work together to provide a structured approach to risk assessment, control implementation, and emergency preparedness.

1. Project Information: This section identifies the specific project, location, and dates of work. Clear project identification ensures the method statement’s relevance and applicability.

2. Hazard Identification: A thorough hazard identification process pinpoints potential dangers associated with the task. This involves considering all possible sources of harm, including physical, chemical, biological, ergonomic, and psychosocial hazards. Each identified hazard should be clearly described.

3. Risk Assessment: Once hazards are identified, a risk assessment evaluates the likelihood and potential severity of harm. This assessment informs the selection and prioritization of appropriate control measures.

4. Control Measures: This section details the specific actions taken to mitigate identified risks. Control measures should follow the hierarchy of controls, prioritizing elimination, substitution, engineering controls, administrative controls, and finally, personal protective equipment (PPE). Each control measure must be described specifically and practically.

5. Step-by-Step Procedures: Clear and detailed procedures outline the safe execution of the task. Each step should be presented in a logical sequence, incorporating the relevant control measures. Procedures must be unambiguous and easy to follow.

6. Competency Requirements: This component specifies the necessary skills, knowledge, and experience required for personnel involved in the task. This may include required certifications, licenses, training programs, and demonstrable experience.

7. Emergency Procedures: This section details the procedures to be followed in case of an emergency. It includes evacuation plans, emergency contact information, and specific responses to foreseeable incidents relevant to the task.

8. Monitoring and Review: A robust method statement includes procedures for monitoring the implementation of control measures and reviewing the effectiveness of the entire plan. This ongoing process ensures the method statement remains current and relevant.

A well-structured method statement, incorporating these key elements, provides a robust framework for managing workplace safety. It facilitates clear communication, promotes proactive hazard control, and ensures a prepared response to potential emergencies, ultimately contributing to a safer and more productive work environment. Regular review and updates maintain the method statements effectiveness in addressing evolving workplace conditions and risks.

How to Create a Work Safe Method Statement

Creating a robust work safe method statement involves a systematic approach encompassing hazard identification, risk assessment, and the implementation of appropriate control measures. This process ensures a comprehensive plan for mitigating workplace risks and protecting worker safety.

1. Define the Scope of Work: Clearly define the specific task, project, or activity the method statement will cover. Include the location, dates, and any specific equipment or materials involved. A precise scope ensures the method statement’s relevance and applicability.

2. Conduct a Thorough Hazard Identification: Systematically identify all potential hazards associated with the defined scope of work. Consider all possible sources of harm, encompassing physical, chemical, biological, ergonomic, and psychosocial hazards. Detailed descriptions of each hazard are essential.

3. Assess the Risks: Evaluate the likelihood and potential severity of harm associated with each identified hazard. This assessment informs the selection and prioritization of control measures. A risk matrix can facilitate this process, providing a structured approach to risk evaluation.

4. Determine Control Measures: Implement control measures based on the hierarchy of controls, prioritizing the most effective methods. Eliminate hazards where possible, substitute with less hazardous alternatives, implement engineering controls, establish administrative controls, and provide personal protective equipment (PPE) as a last resort. Clearly describe each control measure.

5. Develop Step-by-Step Procedures: Outline clear, detailed, and sequential procedures for executing the task safely. Integrate the chosen control measures within each step. Ensure procedures are easy to understand and follow, minimizing ambiguity.

6. Define Competency Requirements: Specify the necessary skills, knowledge, and experience for personnel involved in the task. Include required certifications, licenses, training programs, and demonstrable experience. This ensures competent personnel execute the work safely.

7. Establish Emergency Procedures: Detail procedures for responding to foreseeable emergencies relevant to the task. Include evacuation plans, emergency contact information, and specific responses to potential incidents. Regular drills and training exercises ensure preparedness.

8. Implement, Monitor, and Review: Implement the method statement, ensuring all personnel are aware of and adhere to the outlined procedures. Regularly monitor the effectiveness of control measures and review the entire method statement periodically, updating as necessary. This iterative process maintains the document’s relevance and effectiveness in managing workplace safety.

A robust method statement requires a systematic approach, encompassing clear scope definition, thorough hazard identification, risk assessment, and the implementation of effective control measures. Detailed procedures, competency requirements, and emergency preparedness are crucial elements, ensuring a comprehensive safety plan. Regular monitoring and review maintain the method statement’s relevance and efficacy in safeguarding workers and promoting a safe work environment.

Careful planning and execution of work activities are paramount for ensuring safety in any operational setting. A robust framework for hazard identification, risk assessment, and control implementation provides a crucial tool for mitigating potential dangers and fostering a proactive safety culture. Thorough documentation of procedures, competency requirements, and emergency response protocols ensures clarity, promotes accountability, and empowers workers to actively participate in maintaining a safe work environment. Regular review and adaptation of these plans are essential for addressing evolving risks and maintaining the highest safety standards.

Prioritizing safety through diligent planning and meticulous execution is not merely a best practice but a fundamental responsibility. Investing time and resources in developing and implementing these crucial safety documents demonstrates a commitment to protecting workers, minimizing operational disruptions, and fostering a culture of safety. This proactive approach ultimately contributes to a more secure, productive, and sustainable work environment, benefiting both individuals and organizations.